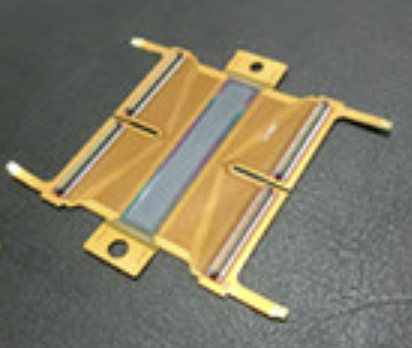

Dev. Ex.

COF board mounting for bonding MEMS sensors

To the FPC substrate sensor unit is opened, the MEMS sensor chip of length 40mm is implemented as a flip chip bonding.

specification

| Special Stipulations | MONSTER PAC® low temperature bonding |

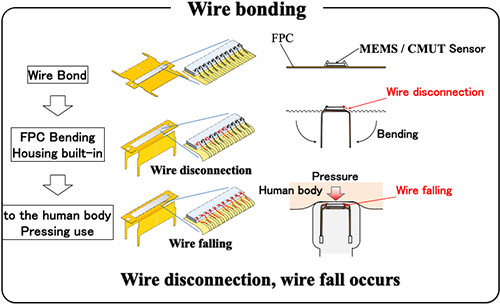

Conventional method 1

wire bonding ▼ (1) When FPC folding of the housing built-in, the wire breaks (2) When pressing against the human body and using it, etc. When pressure is applied, the wire collapses and disconnections ▼ Not implementable

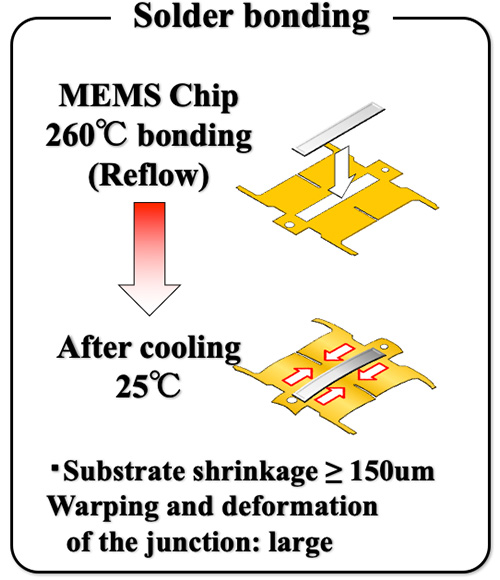

Conventional method 2

Flip chip bonding by solder

▼

After solder reflow (260℃) cooling, the substructure shrinks largely

▼

Warping of joints, non-bonded due to deformed large

▼

Solder not possible

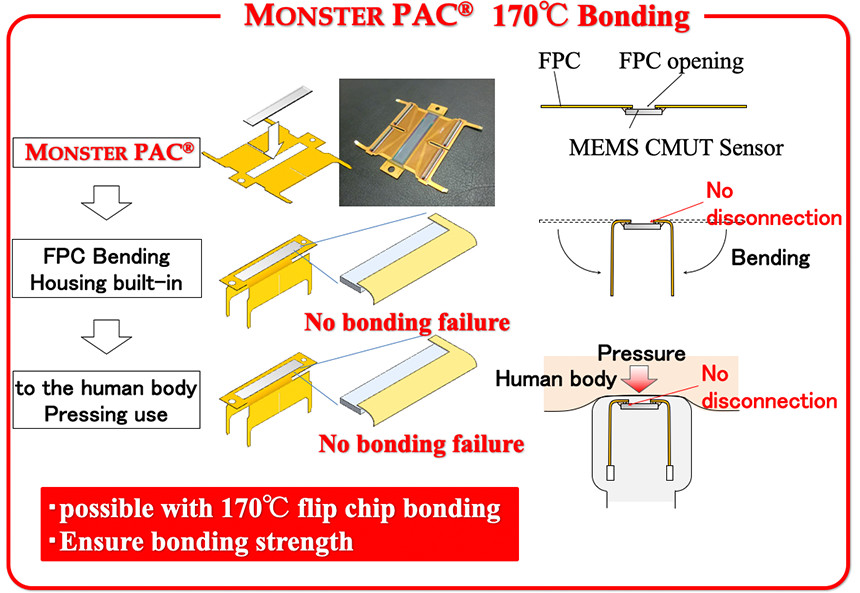

MONSTER PAC® Method

Low-temperature and low-load MONSTER PAC®️ 170℃ bonding

▼

Because there is no wire

(1) No disconnection when housing is built

(2) No collapse or disconnection when pushing the human body

▼

feasible